Smart Agro

Smart Agro

Smart agriculture is an innovative approach in agriculture that uses information and technology to improve agricultural operations. This mainly involves transferring data from the field to the computer system and back. This allows farmers to make better decisions about their operations, which finally yield significantly better results. In essence, smart farming is an efficient way to grow and produce food.

For example, a farmer could use smart agriculture to monitor moisture levels in the land and to inform about crop distribution. This allows crops to be protected from drought and excess moisture at all times. In addition, data collected from the field can inform about fertiliser application and pest control, ensuring that plants are in optimal health at all times. Together, this allows farmers to take advantage of new technology to improve their field operations.

T3Soft offers a complete, hardware-based solution that allows farmers to monitor moisture levels, control irrigation systems, and survey areas that need further watering.

Also, by measuring humidity and temperature in various agricultural crops, it is possible to prevent the appearance of fungi and / or other microbial hazards that may endanger the seed, i.e. the total yield. Previously described represents the essence of the T3Soft Smart Agro system.

The advantages of using this solution are:

• Increase in annual yield / input

• Availability of relevant data from which to identify the main factors influencing the yield

• Receipt of notifications when certain parameters cross the limit values, so acting only on demand

• saving time on controls, a cloud of agricultural land

• savings and optimal use of fertilisers, pesticides,..

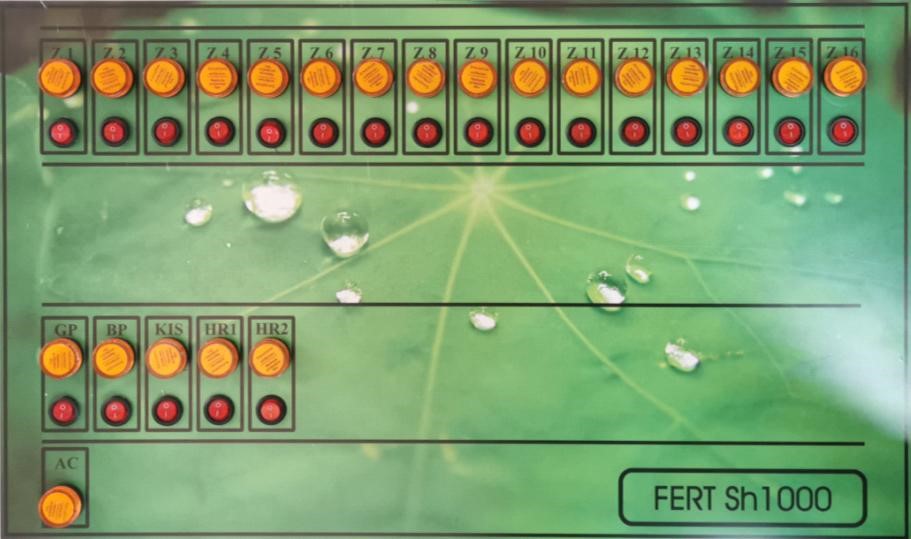

In the framework of Smart Agro solutions we offer systems for plant fermentation. These systems are used for the automatic feeding of plants, as well as surveillance. The heart of the system is a control cabinet which controls 16 outlet valves to the bay zones, then 3 intake valves for acid and 2 nutrients.

When it comes to the suction part of the machine, it has three independent channels for suction and injection into the food or acid system. Hand valves are for fine tuning of food and acid flow levels. The total flow level can be seen on the scale on the rotameter itself (liter / hour), i.e. the height of the float in the rotameter itself. The Buster Pump is located behind the valve and the rotary.

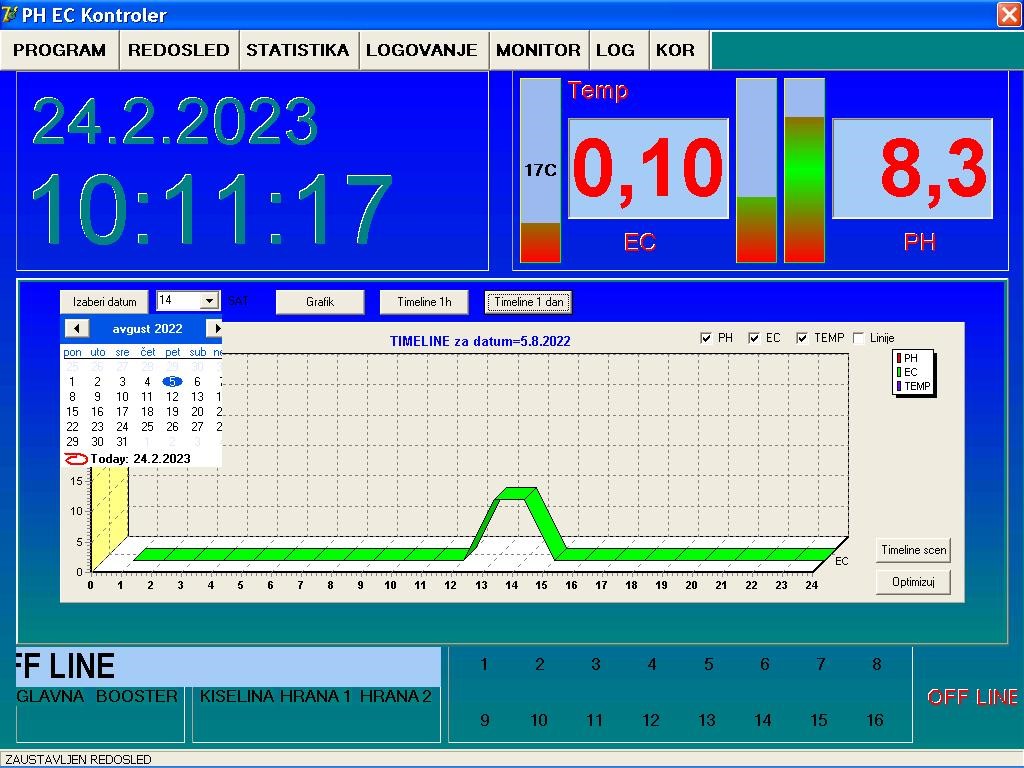

The computer part of the system is used to fully automate the system. Us assistance of the user program, it is possible to assign parameters such as: Electrical conductivity level (EC), acidity level (PH) as well as watering, feeding, etc.

Short video clip that depicts the way which part of this module works, you can see by clicking on the link below: