Smart Industry

Smart Industry

The Smart Industry is a concept used to describe the evolution of related devices, information and technology in the manufacturing industry. The concept of smart production 4.0 includes intelligent machines, automated systems and cloud technology. Manufacturers use smart industry 4.0 to improve production quality, reduce costs and increase safety.

It is a paradigm shift from a society based on information technology to a society based on data. It's a transformation from analog to digital world, where the concept of smart industry 4.0 gets its name. It uses information technology to connect devices, sensors and people. It allows remote monitoring and control of the device without human intervention. Companies use smart industry 4.0 to revolutionize their industries with new ideas and technology.

T3soft, as a company with long-standing experience in the field of digitisation and automation of production, real-time data supply, and the like, offers SmartIndustry software solutions in its assortment. This solution consists of several parts, where the most significant is T3Soft Agile Production.

T3Soft Agile Production is a software system consisting of multiple applications designed to monitor the production process in real time. It is based on the basic principles of the Lean concept and Kaizen methodology. The main benefits of using this software system in the production process are:

- Reducing the number of complaints

- Decreasing the net.

- Improving efficacy

- Lowering stop time.

- Optimizing Brigadier's Service

- Eliminating printing costs

- Interaction and integration with other software

In addition to software, T3soft offers hardware such as touchpad monitors, RFID scanners, sticker printers, etc. Agile Production is a system consisting of several modules, and some of the most important will be listed:

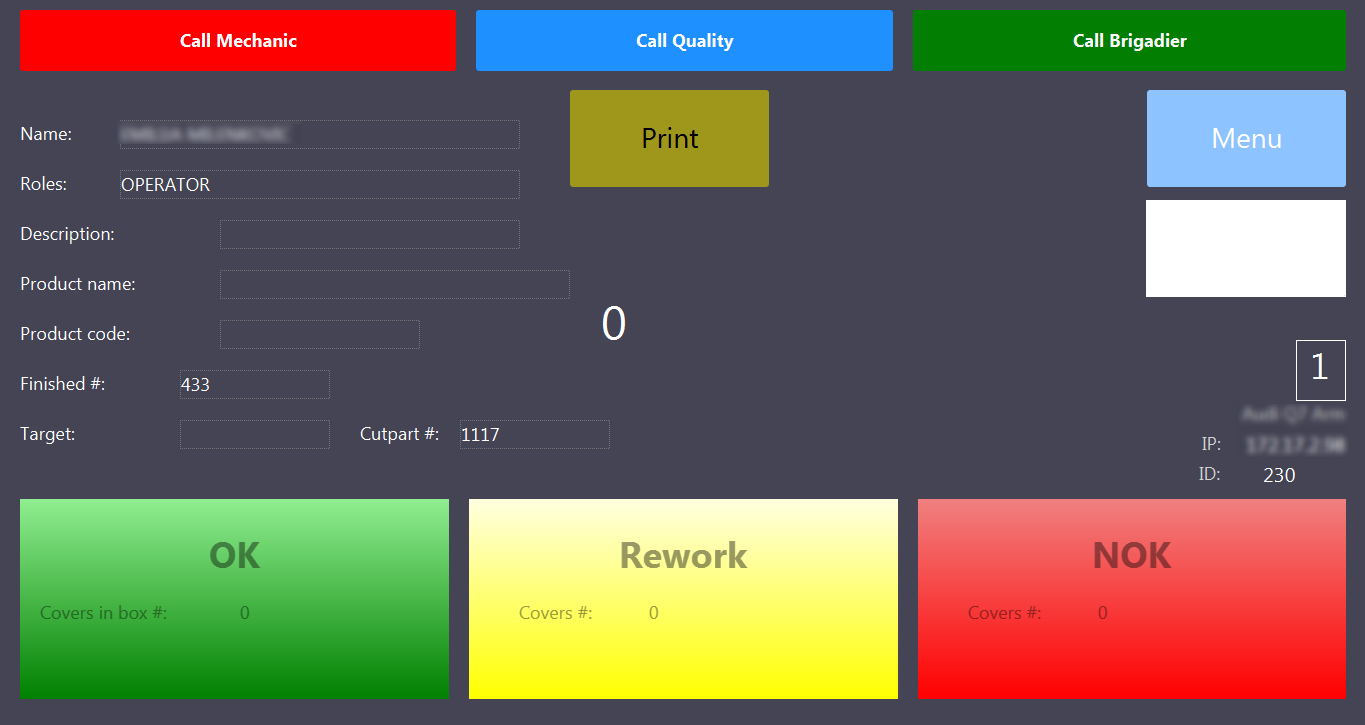

BCClient is a basic application with a number of functionalities, the most important of which are: Loan of the island with material, scanning of the barcode of the product, classification of the quality, monitoring of the implementation, blocking of the work due to a larger scale, printing of labels for boxes of finished products, calling of mechanics, calling of brigadiers, calling of the quality service, internal reporting, list of materials, electronic photographs.

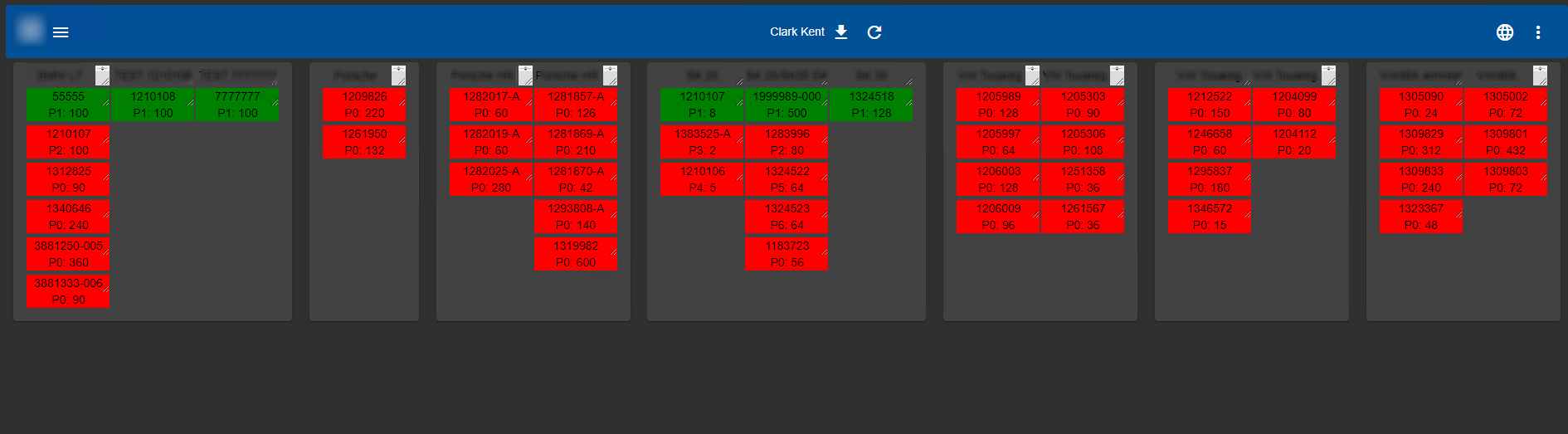

BC ProductionMonitor presents the production semaphore that is shown on the big TV screen and contains data on all parts of the production, the production plan, the current goal, the plan fulfillment, the number of discs and critical locations with discs, as well as the background calculation of the plan fulfillment based on the shift plan and various types of breaks.

Web Alert application for maintenance service with monitoring of all parts of production, which can be divided into multiple targets (depending on number of factories or plant), visual notification to mechanics using the application on the phone, with priority setting, that somewhere there is a problem in production, acceptance of calls for problem solving, measurement of the time of removal of faults, recording of details. The basic purpose of the application is to actually prevent machine failures, and this is possible through the option of preventive maintenance, by creating monthly / annual maintenance plans.

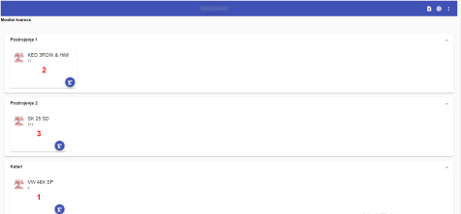

Web Brigadier - the magnate / brigadier scoreboard, which shows on the big TV screen the production plan for each part of the production with data on the product, the required amount of material and the priority of work, directs magicians to locations in the production where they have to carry the production material, in which quantity and tub, integrated with BC Client where operators can call them over the button on the screen.

Web Admin – web application for complete administration and reports